Jack Rattle Stops

Checkout securley with

- Description

- Specifications

- Dimensions

- Front Runner

- 🛡️ Fitment Advice

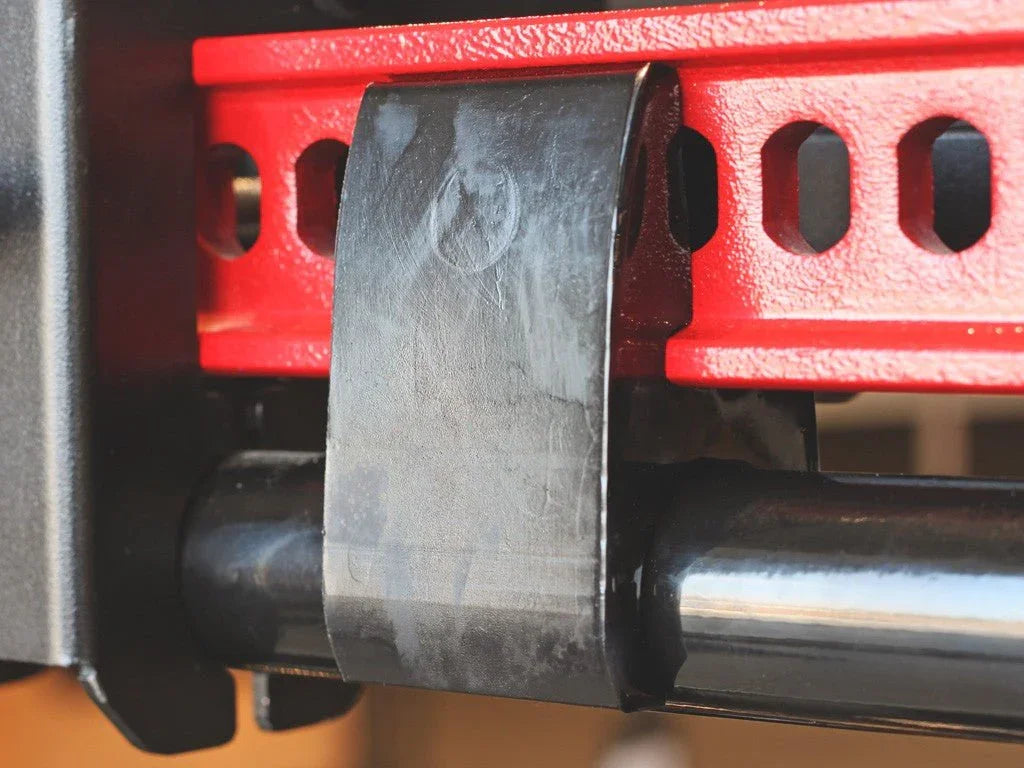

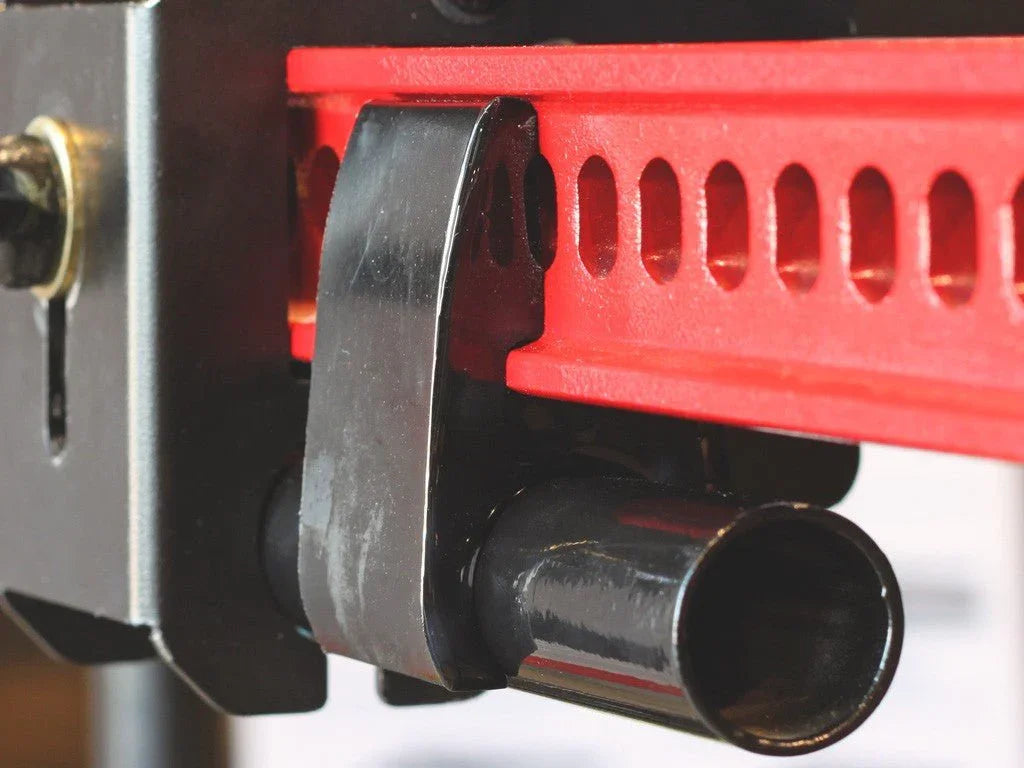

Formed to fit over the Hi-Lift Jack shaft and handle to prevent movement of the Hi-Lift Jack parts when transporting or storing.

A ''gripper knob'' holds the Stop tightly in place in between the rungs of the Hi-Lift Jack shaft.

Suitable to use with the {JADA010} and can be used in any mounted position.

Made of black cold cure elastomer polymer plastic and with a hardness rating of Shore 80 A according to the durometer scale.

Fits all types of Hi-Lift Jacks.

Removal of the Front Runner Jack Rattle Stop is needed to release the handle and operate the Hi-Lift Jack.

Materials used:Cold cure elastomer polymer plastic

Product Dimensions:190mm (7.5) L x 155mm (6.1) W x 45mm (1.8) H

Weight:0.13kg (0.3lbs)

Travel. Dream. Design. Build. Test. Evolve. Repeat.

Legend has it that Front Runner was conceived between a 1988 Land Cruiser 70 and a 1992 Mercedes G-Wagen in Botswana, around a campfire, near a majestic Baobab, amongst elephant tracks, by a handful of friends from South Africa with backgrounds in engineering, design, manufacturing and off-road racing. After suffering through numerous equipment failures on their expeditions around the world, they decided to take their shared passion for vehicle based adventure travel and dream up new, smart gear and build it stronger than… well, as they put it, “stronger than the elephants at the watering hole 1 klick over.”

And just like that, before the moon gave way to the sun, we were born.

With the gruelling African bush as a testing ground, we at Front Runner focused on a tough love approach to developing products. With both feet facing the future and little sentimentally for mediocre ideas of the past – common approaches to off-road vehicle product design were quickly jettisoned in favor of innovation, new materials, and superior manufacturing practices.

Today our products have a well deserved reputation (if we don’t say so ourselves) for quality, intelligent design, and durability. Our manufacturing facility just outside of Johannesburg, South Africa features in house laser cutting, bending and powder coating. Our CAD designed products by a team of engineers and built by skilled craftsman in our ISO-9001 : 2015 Certified factory.

Our roof racks, water tanks, tents, awnings, drawer systems and camping accessories are enjoyed, used and abused around the world by casual campers, the U.N., overlanders, NGOs, outdoor enthusiasts and extreme athletes.